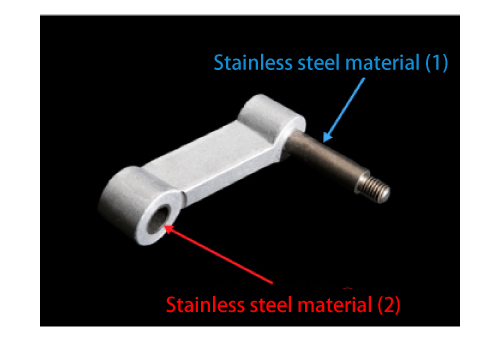

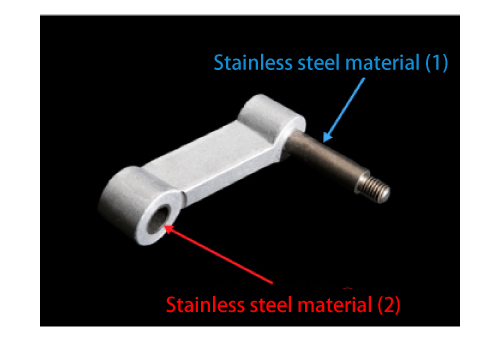

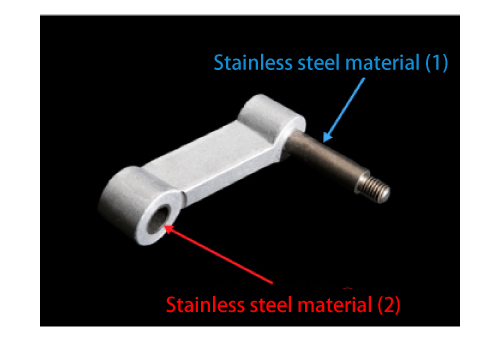

In the past, stainless steel bolts (stainless steel material 1) were tapped onto aluminum alloy castings that

were roughly the same shape as that of the photo above.

However, the sliding parts (stainless steel material 2) gradually wore out and rattling would occur.

Thus, the stainless steel material (1) and (2) were combined through insert casting to improve

the wear resistance without changing the overall shape.

In addition, this reduced the number of tapping and bolting operations, allowing for a significant reduction in cost.