With the introduction of Yamazaki Mazak VCN-530C (maximum machining size: 1050 x 530 x 510 mm),

we are now able to produce prototypes of aluminum parts with complex shapes through cutting.

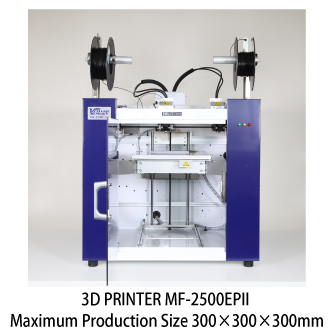

After confirming the shape with a model output from a 3D printer, the actual aluminum parts can be manufactured

using a machining center, making it possible to evaluate the strength and performance of the parts.

In addition, by combining machining aluminum castings with a machining center,

we can process products with complex shapes in a shorter period of time.