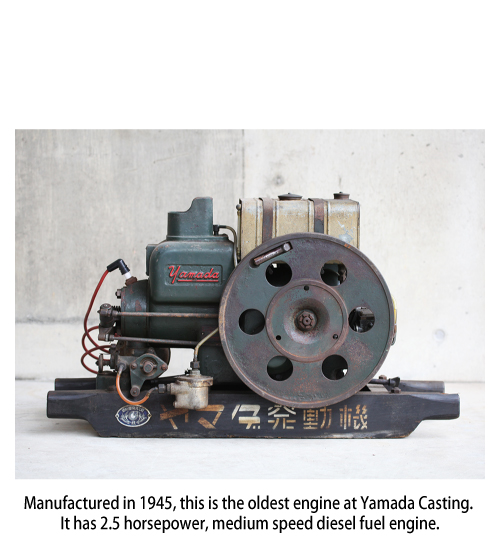

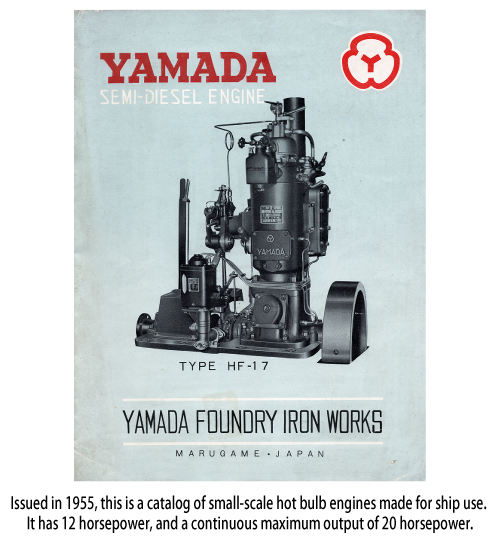

1918 Kanematsu Yamada, the founder of Yamada Casting, established an iron factory in Marugame-shi, Kagawa

to manufacture and sell internal combustion engines for agriculture and marine use.

1928 We opened a branch factory in Seto-shi, Saga, to sell and repair products.

1935 We opened a casting factory in Sakaide-shi, Kagawa.

1944 We moved to our current location in Minatomachi, Marugame-shi by integrating the factories

in Marugame-shi and Sakaide-shi.

1946 With the dissolution of land, sea, and air force production after World War II,

we restarted production of internal combustion engines for fishing boats.

1957 We halted production of internal combustion engines for agricultural use and began producing

machinery for industrial use.

1960 We became a subcontract factory of Koyo Seiko Takamatsu factory and began turning ball bearing parts.

In addition, we gradually decreased our production of internal combustion engines.

1961 We became a stock company with a total value of 5 million JPY, and Kanematsu Yamada was nominated

as company president.

1965 Our capital stock increased to a total of 10 million JPY. We also streamlined our foundry, opened an

electrostatic coating plant, and began producing pillow block bearings.

1966 We ceased production of all industrial machinery.

1973 We opened an expanded polystyrene molding plant and began producing fish boxes.

1975 We upgraded the molding machine in the foundry to a Hunter high pressure automatic line.

1976 The company president, Kanematsu Yamada, assumed the position of Chairman and Representative

Director CEO, and Fumio Yamada was nominated as the second President and CEO.

1978 Our capital stock increased to 15 million JPY.

1982 We began using sand casting to produce aluminum alloy castings.

1983 We began using gravity die casting to produce aluminum alloy casting.

1994 We introduced a CNC milling machine with ATC.

2005 We built a new foundry and separated it from our expanded polystyrene division.

2012 President Fumio Yamada became CEO and Toshifumi Yamada assumed the role of third President.

2013 We installed two new tilting gravity die casting machines.

2015 We installed a 3D printer called MUTOH 3D Magic Egg MF-1150.

2016 We began casting pure aluminum, which has significantly different characteristics from those of general alloys.

2017 We introduced aluminum degassing equipment (GBF-FH) as well as a melting furnace designed to process

pure aluminum (500kg). We also began production of pure aluminum rice cookers for commercial use.

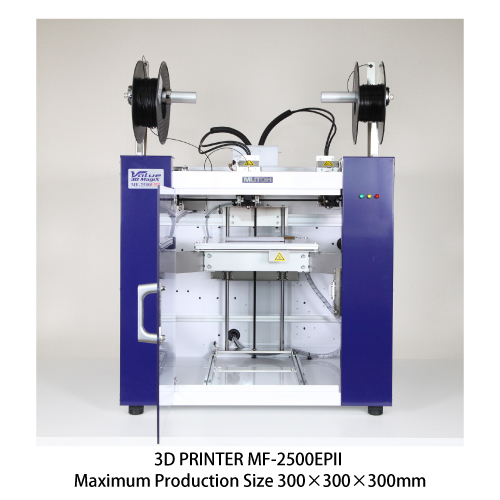

2020 We installed a 3D printer called MUTOH Value3D MagiX MF-2500EPⅡ, and we installed a Yamazaki Mazak

VCN-530C machining center

.