In general aluminum casting alloys (AC4C, etc.), alloying elements (Si, Mg, Cu, etc.) are added

in order to achieve both castability and strength.

On the other hand, pure aluminum (97% or more Al) has excellent corrosion resistance, ductility,

and anodizing properties due to the fact that they have fewer added elements compared to general alloys.

However, it has the disadvantage of inferior castability and strength compared to general alloys.

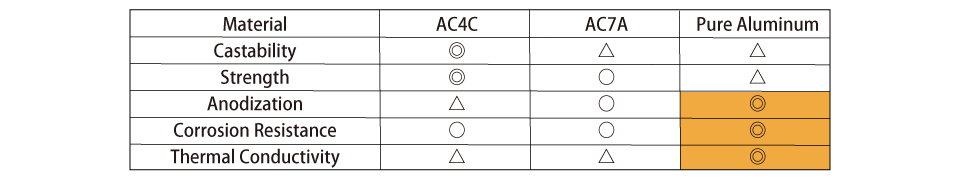

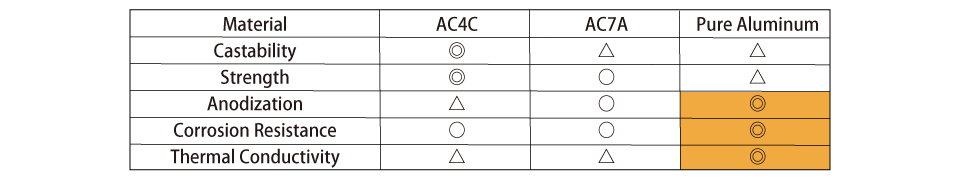

The table below compares general aluminum casting alloys with pure aluminum.

Since 2016, we have been working on casting using pure aluminum,

which has significantly different characteristics from general casting alloys.

We also have experience manufacturing gas rice cookers made of pure aluminum for commercial use.

Pure aluminum casting products are more ductile and expandable than products made of general casting alloys,

and can be pressed after casting.

Casting and pressing enable free modeling that differs from conventional processes.