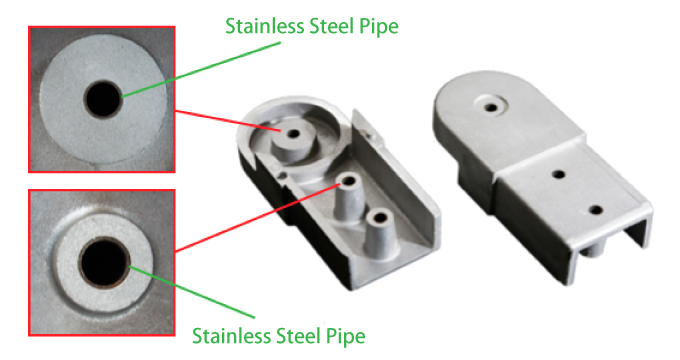

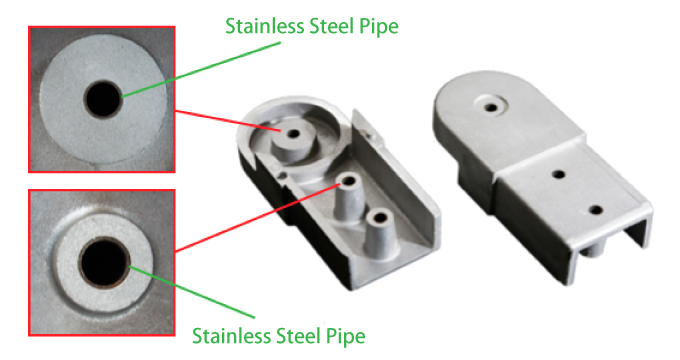

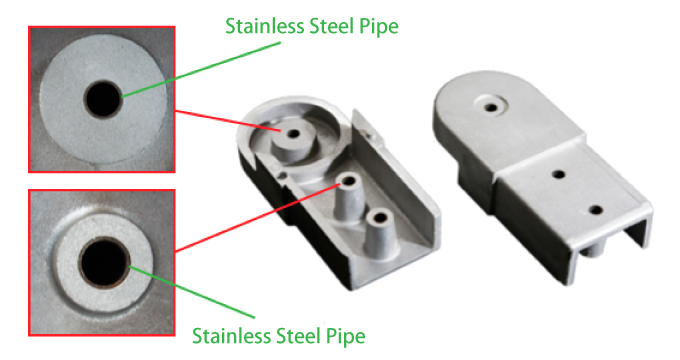

For products of this shape, the process of drilling holes is usually carried out

after the aluminum alloy casting is completed.

Because this product contains two separate parts that fit together, the accuracy of the holes’ dimensions

and the strength of the fasteners is crucial.

By combining the stainless steel pipes into a single piece using insert casting, we were able

to improve the accuracy of the hole positions and the strength of the fasteners, while reducing overall costs.